Our agricultural roots deeply inform Eion’s focus on building trusted relationships with farmers, partners, and the communities where we operate. The foundation of this trust rests on ensuring that Eion’s deployment of enhanced rock weathering (ERW) works with farmers’ fertility plans and provides economic benefits.

Eion co-founder and CEO Adam Wolf joined the OpenAir community to talk about responsibly deploying ERW (head to the bottom of this blog post to watch). This post summarizes key points from the talk, including:

- Optimizing the agronomic dimensions of olivine applications

- Creating benefits for farmers with CO2 removal

- The history of safe use of silicate rock applications on farmland

- Our approach to responsibly scaling the ERW value chain

Why Farmers Use Ag Lime as a Soil Amendment

Farmers rely on soil amendments to meet crop nutrient requirements. A key ingredient is conditioning the soil pH to make nutrients more bioavailable. A good soil pH supports the activities of microorganisms cycling nutrients, helping farmers meet their yield goals.

If the soil is too acidic—often the result of long-term fertilizer use—farmers can apply soil amendments to get the soil closer to the optimal pH. Traditionally, agricultural lime (ag lime) has been the soil amendment of choice for this purpose based on performance, availability, and cost. In the field, trusted crop advisors and PhD agronomists take samples, determine soil pH, and make precise zone-level recommendations for how much ag lime to apply.

Silicates as an Ag Lime Substitute

While the idea of using silicate rocks as soil amendments may seem innovative, it actually dates back to a patent from 1881.

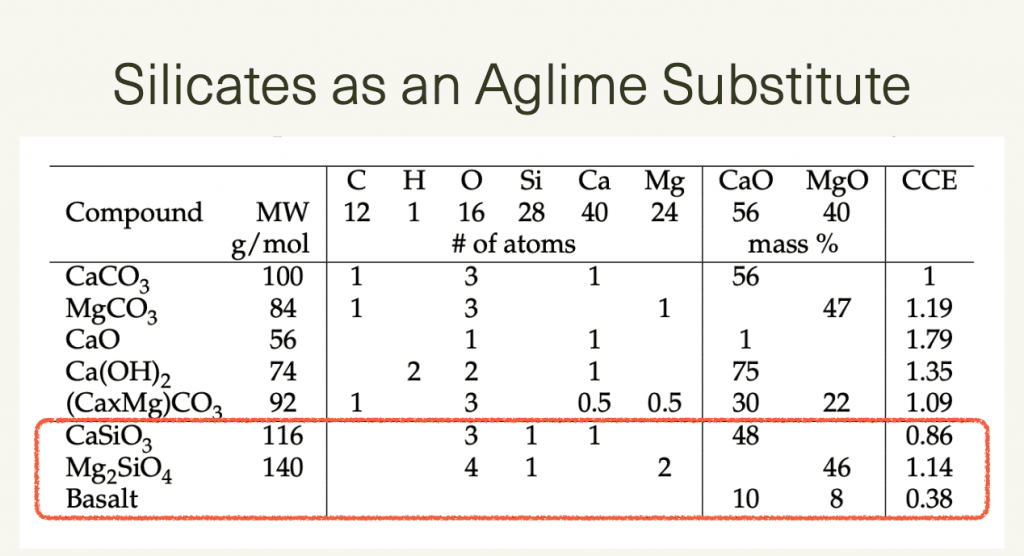

The chart below shows the elemental composition of ag lime (CaCO3 or calcium carbonate) along with various silicates. The important thing to direct your attention to is the column “CCE” or Calcium Carbonate Equivalent (CCE), which essentially shows how well this silicate works compared to an ideal ag lime. Often commercially available ag limes have a CCE well below 1.

Calling on Adam’s experience as an ag chemist and working within agronomic handbook recommendations for standard ag lime use, Eion set out to develop a silicate product that would not only remove carbon effectively, but would also work as a high-performance ag lime substitute.

How We Optimized Olivine for Agriculture

Olivine (Mg2SiO4 in the chart above) is a silicate that gets its name from its olive green color and is one of Earth’s most abundant minerals. It’s naturally found on beaches in Hawaii and the Galapagos as well as the shores of Europe’s deepest lake, and forms many of the San Juan Islands in Washington State. Although this mineral is generally known for its high heat capacity (it’s mostly used for steel castings), it was recognized since the 1940s as a means to improve the availability of phosphate fertilizers in crop production.

For our purposes, as one of the fastest weathering silicate minerals, it has the potential to outperform many ag limes for conditioning soils for crops. As you see in the chart, its CCE is 1.14, meaning farmers may need to use less than standard ag lime to achieve the desired effect. Replacing ag lime with olivine requires no extra work or change in regular farm operations. It’s applied every 2-3 years just like ag lime using the same equipment.

While olivine has been a legally approved and labeled agricultural input since the 1940s in the United States, Brazil, New Zealand, and Australia, its use has been somewhat limited because of price. Few farms are advantageously positioned near olivine sources, and transportation can be expensive. We also noticed a lack of a widely available olivine product ready to apply to fields that could easily replace ag lime.

So, we set out to create Eion’s olivine product, “CarbonLock.” We found an optimal particle size and dissolution rate that delivers soil benefits quicker than standard agricultural lime while predictably and reliably removing carbon dioxide. And because CDR (carbon dioxide removal) subsidizes the cost, we’re now able to offer a high-performing soil amendment to farmers that otherwise would find olivine out of reach.

Considerations on Health and Safety

Let’s take a broader view to discuss the implications of using silicates on cropland at a large scale. Since the 1940s, about 2 million tons of serpentine (a cousin of olivine) have been applied on cropland in New Zealand without adverse consequences, and olivine is sold today as a magnesium fertilizer in Oregon, Washington, and California.

But deploying enhanced rock weathering as a carbon removal solution holds the potential for a much greater scale, and to sensibly work through potential impacts, we’ve used data and risk exposure models from the Environmental Protection Agency (EPA) to determine our safety guardrails. The EPA’s comprehensive 2,000-page technical document offers all the equations, parameters, and data used to develop regulations. We’ll dig into the technical details in a moment.

To avoid burying the lede:

The Environmental Protection Agency’s (EPA) work shows no apparent risk from applying silicate rocks including olivine. We have reviewed all available research about olivine use, and to the best of our knowledge, no actual harm has been reported due to the application of olivine on farmland, including impacts on water, crops, livestock, wildlife, microorganisms, and food.

Now, let’s dig into the EPA’s work.

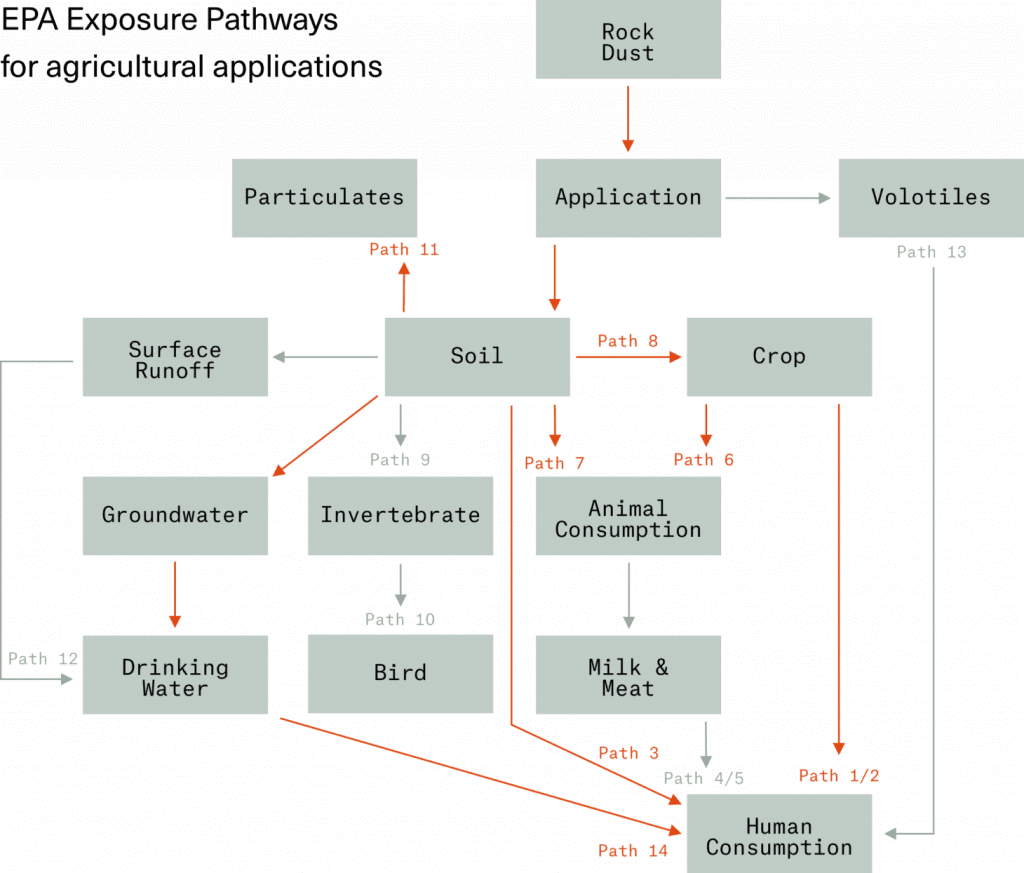

The EPA evaluated 14 different pathways where crop amendments could potentially lead to harmful exposure. (Their focus was on municipal solid waste, but many of the principles apply to olivine and silicates generally.) We’ve marked the relevant pathways in red.

Six of these pathways show no concerns (for example, olivine does not volatilize or bioaccumulate). The others are scenarios where it would require continuous application for many hundreds if not tens of thousands of years to accumulate in soils to a level of concern. And even then, the EPA found this unlikely to happen because a steady state between accumulation and loss is reached in about 150 years.

The takeaway: There’s little potential that soil concentrations can reach regulatory thresholds, let alone levels that lead to harm.

Eion’s Approach to Responsibly Deploying Enhanced Rock Weathering at Scale

While available data and research points to the safe use of silicates and olivine, we are conservative in our approach and have implemented a number of operational guardrails to ensure we are acting as responsible land stewards.

We source our olivine from suppliers who hold very high environmental standards, like Sibelco, which has been in operation for 150 years and is recognized for their safety and health record as well as commitment to environmental stewardship.

Next, Eion works with fields only when growers and their trusted crop advisors determine rates for olivine application that are agronomically appropriate. These are highly specialized professionals with hands-on experience in agronomy and land management who have an incentive to operate in the best interest of the grower.

We’re conservative when it comes to olivine application rates, and recommend approximately 10-20 times less than what is typically published in the academic literature. Eion’s recommended application rate of 1-2 tons per acre is just enough rock to gently boost the soil’s pH.

Finally, our before-and-after sampling methods provide a touchpoint to continuously monitor concentration levels. By actively measuring the soil and olivine material, we ensure levels never exceed safe thresholds for plants, animals, or humans. This intentional feedback loop is pivotal to our commitment to responsibly scaling ERW and upholding scientific rigor.

At the end of the day, Eion is growing at the speed of trust. We’re accountable to growers and the communities where we operate, and are committed to learning out in the open for the benefit of the ERW category overall. If you’d like to dig deeper into our work, learn more about our process and science.

Want to watch the full segment? Here’s Adam discussing responsible deployment of ERW during a talk with the OpenAir community:

Video credit: OpenAir Collective