Our co-founders Adam and Elliot recently joined the OpenAir community to discuss enhanced rock weathering (ERW). If you have an hour and a half to spare, check out the full video at the bottom of this post. If not, keep reading for the spark notes.

This recap covers the strengths of ERW as a carbon removal pathway, how we measure it, and considerations for scaling it — all with a dose of geochemistry and agronomy for good measure.

Let’s dig in!

- Key CDR Questions: Is it real? Can it scale?

- ERW Is Real: How We Reliably Measure ERW

- ERW Can Scale: Deploying Gigatons of Silicate

- Farming Communities Play a Key Role in Scaling ERW

Key CDR Questions: Is it real? Can it scale?

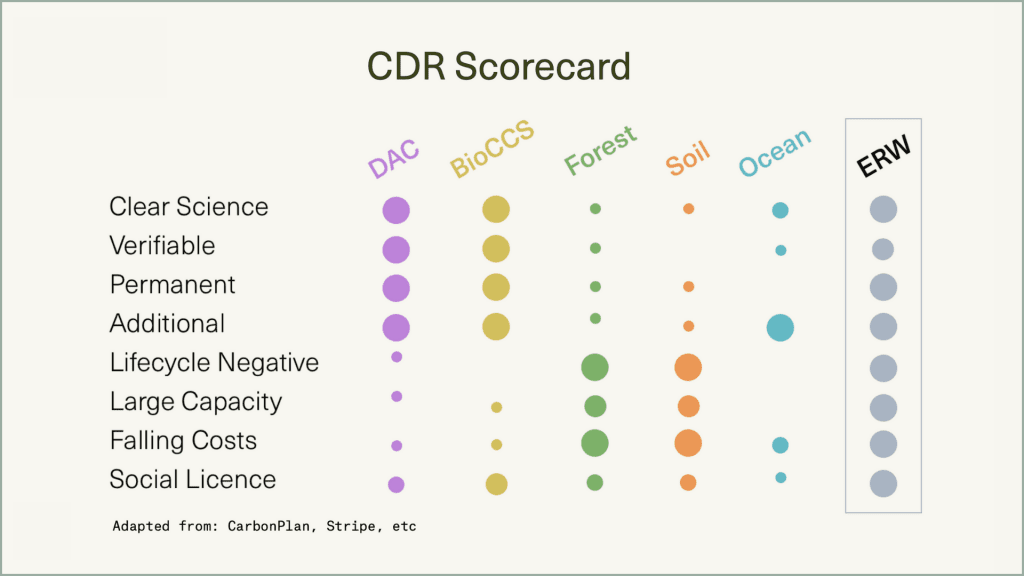

To get at these two critical questions, let’s consider the carbon removal pathway scorecard from CarbonPlan, which compares critical aspects of high-quality CDR. It’s easy to see a pattern in this graph: Expensive, low-scale CDR on the left. Affordable, high-scale CDR on the right. The takeaway? There are trade-offs for every pathway.

Another handy way to think of this is by using the open and closed systems framework.

Closed system pathways like DAC and biochar score high on verifiability and permanence, which makes sense. These are man-made processes specifically designed to remove carbon dioxide. The trade-off? Closed systems take a lot of work to build and are expensive to scale capacity.

Open system pathways like soil, forests, oceans, and weathering use intentional interventions to kick-start or speed up Earth’s natural ability to remove massive amounts of carbon. Nature does the heavy lifting using processes designed and optimized over millennia. The trade-off? Open systems are notoriously hard to measure.

Enter enhanced rock weathering. Looking at the scorecard, it checks all of the boxes: the science is proven, and ERW can provide a meaningful chunk of the emissions removal we need. So why hasn’t this pathway taken off? Since it’s an open system pathway, until now it’s been tough to measure.

Key Takeaways:

- CDR pathways can be framed as closed systems (relying on man-made engineering) and open systems (tapping into Earth’s elegantly designed processes).

- There are trade-offs with every CDR pathway. Some are easier to measure and precisely control but expensive to build. Others are more affordable but harder to measure.

- ERW checks the boxes for effective and affordable carbon removal. Plus, it can scale to remove a meaningful amount of carbon dioxide. But until now, ERW has been hard to measure.

Learn more about the basics of enhanced rock weathering>>

How We Reliably Measure Enhanced Rock Weathering

Eion developed a measurement process for both accuracy and large-scale capacity deployment of enhanced rock weathering. It’s interesting science at the intersection of our team’s life work in agriculture, geochemistry, and soil science.

Before we get into a step-by-step of how it works, it’s important to understand that we started from the need to design an accurate measurement approach that could work at gigaton scale. To do that, we intentionally fit ourselves into the regular business operations of crop advisors, farmers, and ranchers. It’s not the easiest thing logistically speaking, but it works and makes it relatively easy to scale the accurate measurement of this highly scalable carbon removal pathway.

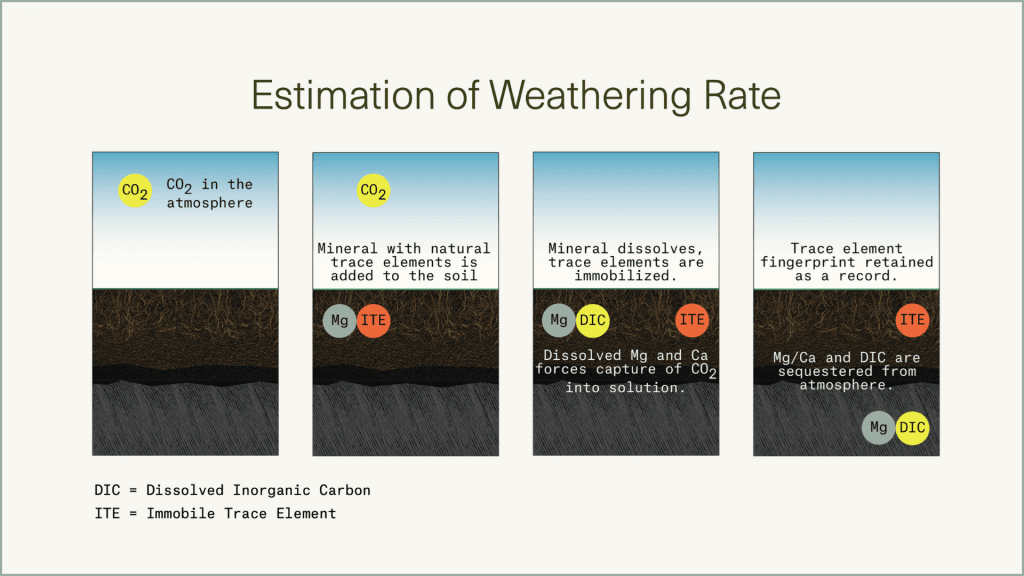

Now on to how it works. We’re basically running a before-and-after test: what did the soil look like before we put the rock down, and what does it look like after? To get a full explanation, watch Elliot’s overview of the geochemical process at 12:15 in the video at the bottom of this post.

For simplicity, think of it this way:

- Before applying rock, we take soil samples and measure magnesium and immobile trace elements (trace means “small quantities”).

- Rock goes on fields, and that rock includes added magnesium and immobile trace elements (immobile is like “stationary,” meaning they don’t dissolve or move out of the soil in the weathering process).

- Atmospheric CO2 dissolves into water within the soil.

- As the rock breaks down and dissolves into the soil, magnesium ions pair up with carbon (the dissolved CO2 from Step 3).

- Now bound together, magnesium and carbon seep through the soil and into the water table, moving through rivers to eventually reach their final destination in the ocean.

- After several months, we measure what’s left behind in the soil. Specifically, we want to see how much magnesium and immobile trace elements remain.

By comparing the before and after, we can tell how much of the applied rock weathered (dissolved), how much magnesium moved through the soil, and ultimately how much atmospheric carbon was removed.

Our field trials show that ERW doesn’t perform the same in all conditions. One example, called the strong acid effect (essentially an inefficiency in the process), is where magnesium moves through soil together with another molecule other than carbon. We can account for this in our measurement approach and ultimately avoid overestimating the carbon removed.

At this stage, it’s essential to grow our understanding of how it performs in various conditions and where it works best. So far, we’ve found strong results in the Southern U.S., where the soil is acidic and the climate is wet, so we’re focused there first.

Elliot and the Eion science team are working hard to distribute our research and translate Eion’s measurement approach into a methodology others can use widely to advance ERW. That process involves working groups of scientists from many organizations and ERW companies, white papers, and peer review. This work is already in the publication pipeline.

Key Takeaways:

- Eion’s measurement approach was designed to scale by fitting into existing soil sampling processes used by crop advisors, farmers, and ranchers.

- In the lab, we’re doing a before-and-after test and looking at magnesium and immobile trace elements to quantify the carbon removed during weathering.

- Directly sampling soil helps us understand how ERW performs in variable conditions and avoid overestimating how much carbon is removed.

- By fitting into soil sampling processes that operate at scale, we can operationalize an accurate measurement process and enable large-scale deployment of enhanced rock weathering.

Deploying Gigatons of Silicate

Taking a step back, what are silicate rocks and why are they used in agriculture in the first place?

The use of minerals (like olivine or lime) as a soil amendment is a practice that dates back over a century to balance pH levels. Farmers have tended to use ag-lime (agricultural limestone) because it’s the more widely available option. Since the need to remove carbon changes the economic equation, Eion can now offer farmers olivine as an ag-lime replacement that delivers the same soil benefits while efficiently removing carbon along the way. Olivine has been approved and sold as an ag input for decades in the U.S., Australia, New Zealand, and Brazil.

Because olivine isn’t as widely used yet, there’s still room for improvement in optimizing its performance for both farming and carbon removal. That boils down to tweaking the fineness factor, directly impacting how fast the olivine dissolves and thereby weathering and removing carbon.

Here’s where Eion’s leadership in measuring ERW intersects with our work to innovate olivine for use in agriculture: direct soil sampling gives us the ability to test and optimize CarbonLock (our olivine mineral) to ensure it has excellent soil conditioning benefits and weathers at a rate that works for carbon removal. Because Eion measures everything directly, we’re building a robust data set about how variable soil conditions and olivine fineness factors perform.

Now, when we’re talking about tweaking anything in agriculture, it’s critical to ensure it’s safe. After all, we rely on the soil to feed us.

We know that since the 1940s, two million tons of olivine have been applied in New Zealand without known ill consequences. But we’re contemplating gigatons for carbon removal, not millions of tons. So to explore what gigatons of silicate application could mean for soil and water, we relied on a resource developed by the EPA to help assess exposure pathways for applying biosolids to croplands (more info at 27:53 in the video at the bottom of this post).

Analysis based on this EPA resource shows no apparent risk from applying silicate rocks like olivine and basalt at scale:

- No concerning signals about surface water runoff

- No noted issues with groundwater

- No unsafe accumulation of metals in the soil or food

Our team is currently working on a publicly available summary of all the third-party research we’ve collected and a look at Eion’s field trials relevant to health and safety. It’s essential to deploy ERW safely, and Eion is committed to advancing this work in a responsible manner that prioritizes real-world data.

Key Takeaways:

- Olivine has been approved and sold as an ag input for decades in the U.S., Australia, New Zealand, and Brazil.

- Based on our experience and the research we’ve reviewed, applying silicate rocks to land does not negatively impact soil or waterways. All standard agricultural safety precautions should still be taken when using the rock.

- The need to remove carbon changes the economics of broadly using olivine in agriculture. Now, Eion can offer CarbonLock (our olivine mineral) as a soil amendment that delivers the same benefits as ag-lime while efficiently removing carbon.

Learn more about how Eion responsibly deploys ERW>>

Farming Communities Play a Key Role in Scaling ERW

At Eion, when we think about scaling, we focus on how our business can benefit people on the ground. When we talk about leveraging the abundance of agricultural land in the world, we’re looking to agricultural communities to be our partners and play a significant role in decarbonizing our economy. That’s why we must pay attention to not just what we build, but how we build, and ensure our work benefits the broadest swath of people possible.

The farm is the site of the carbon removal, but getting everything to that point and even afterward relies on a network of small- and medium-sized regional businesses. These are Eion’s partners—the crop advisors and agronomists, the truck drivers and barge operators transporting CarbonLock, and the mill operators smashing olivine to bits—and to whom we hold ourselves accountable.

In light of this commitment, we’re excited to announce that Eion is opening an office near Vicksburg, Mississippi. Over the coming weeks, we can’t wait to introduce you to all the people we work with on the ground and in the field.

Learn more about Eion’s farmer-first approach and hear from a few of our partners>>

Still curious after reading this summary? Watch the full video on Eion’s approach with Adam and Elliot:

Video credit: OpenAir Collective